Dozer Edge‑Cutting 107‑3746: Compatibility with Caterpillar 938 Series

The Dozer Edge-Cutting 107-3746 represents a precision-engineered cutting solution specifically designed for seamless integration with Caterpillar 938 Series machinery. This compatibility ensures optimal performance in demanding earthmoving applications, where blade durability and precise fit directly impact operational efficiency. The 107-3746 cutting edge delivers enhanced material penetration and extended service life, making it an essential component for maintaining peak productivity in construction and mining operations. Understanding this compatibility relationship helps procurement professionals make informed decisions that maximize equipment uptime and minimize maintenance costs.

Understanding Dozer Edge-Cutting 107-3746 and Its Compatibility with Caterpillar 938 Series

The Dozer Edge-Cutting 107-3746's excellent dimensional requirements and sophisticated metallurgical composition are the sources of its technical superiority. This cutting edge's designed shape ensures a stable connection and the right blade angle for optimal cutting efficiency, matching the mounting system of Caterpillar 938 Series loaders exactly.

Technical Specifications and Material Composition

High-carbon steel structure and specific heat treatment techniques are used in the Dozer Edge-Cutting 107-3746 cutting edge to improve impact tolerance and wear resistance. With bolt hole designs and mounting surfaces that ensure flawless installation without modification, the blade's dimensions exactly match those of Caterpillar's original equipment specifications. This precise manufacturing method preserves the structural integrity needed for heavy-duty applications while removing compatibility issues. The performance qualities of the blade are greatly influenced by the choice of material. Excellent hardness ratings are provided by the premium steel composition, which also maintains enough toughness to endure shock loads experienced during operation. These qualities are further improved by heat treatment procedures, which provide a surface that resists wear and keeps its sharp cutting edges for prolonged usage.

Operational Benefits and Performance Enhancement

Measurable operating benefits result from the 107-3746 blade's compatibility with Caterpillar 938 Series machinery. By minimizing stress concentrations that can cause premature failure, the exact fit guarantees the best possible load distribution across mounting points. This engineering strategy maintains steady cutting performance while extending the lifespan of the equipment and blades. The Cat 938 Series loaders' hydraulic capabilities and operating parameters are complemented by the blade's design features. By optimizing material flow and penetration force, proper blade geometry allows operators to maximize output while using less fuel and putting less mechanical strain on the machine's drivetrain components.

Maintenance Requirements and Best Practices

Following prescribed maintenance procedures is necessary to keep the 107-3746 cutting edge operating at its best. Frequent examination of cutting edge geometry, blade wear patterns, and mounting hardware aids in spotting any problems before they affect operation. By enabling conventional tools and methods to carry out required changes and replacements, the compatibility design streamlines maintenance operations. Throughout the service life, secure attachment and optimum performance are guaranteed by appropriate mounting sequence processes and installation torque standards. Without specialized training or equipment adjustments, maintenance staff may adhere to established Caterpillar processes thanks to the uniform design.

Comparing Dozer Edge-Cutting 107-3746 to Other Market Options

Significant differences in cutting-edge performance, compatibility, and value proposition across various manufacturers and product lines are revealed by market study. Precise engineering, high-quality materials, and demonstrated field performance across a variety of operating circumstances make the Dozer Edge-Cutting 107-3746 unique.

Performance Metrics and Durability Analysis

Comparative testing shows that the 107-3746 has better wear characteristics than other state-of-the-art choices. Extended service life under standardized wear circumstances is shown by laboratory study, and field observations across a range of soil types and operating settings corroborate these results. The blade lasts longer than many of its rivals, which lowers the need for replacements and the related downtime expenses. Under typical working circumstances, durability parameters include resistance to edge chipping, impact damage, and abrasive wear. In terms of service life and performance consistency, the 107-3746 matches or surpasses OEM standards while continuously outperforming generic equivalents.

Cost-Benefit Analysis and Value Proposition

The benefits of the 107-3746 cutting edge in terms of total cost of ownership are shown by economic analysis. The longer service life and lesser maintenance needs usually translate into cheaper running expenses per hour when compared to less costly options, even if the original purchase price may differ amongst vendors. The guarantee of compatibility removes the possibility of fitting problems or performance deterioration that might arise from using cutting edges that are not optimized. In situations where downtime costs are higher than blade replacement prices, this dependability factor adds a substantial amount of value.

User Feedback and Industry Recognition

Operators' and fleet managers' field reports constantly emphasize the 107-3746's dependable performance and trouble-free operation. Because of the blade's established specs and broad availability via approved distribution networks, maintenance departments say that inventory management has become easier. Compatibility certificates and OEM approval ratings that confirm the blade's fit with Caterpillar machinery are examples of industry acknowledgment. These recommendations provide procurement experts more assurance when assessing state-of-the-art solutions for their fleets.

Procurement Guide for Dozer Edge-Cutting 107-3746

Strategic procurement of cutting edges requires understanding of supply chain dynamics, quality verification procedures, and supplier selection criteria. The 107-3746's widespread availability through multiple distribution channels provides flexibility in sourcing strategies while maintaining quality standards.

Supplier Evaluation and Selection Criteria

Assessing production capabilities, quality control systems, and certification status are all part of finding competent suppliers. In addition to offering warranty coverage and technical support services, authorized distributors usually maintain inventory levels that enable quick delivery. OEM compatibility certificates and manufacturing quality requirements should be verified as part of the assessment process. For processes that depend on regular blade availability, supply chain dependability becomes very crucial. More guarantees of ongoing product availability and technical assistance throughout the procurement relationship are provided by reputable suppliers with a track record of success in the distribution of heavy equipment parts.

Pricing Strategies and Volume Considerations

Volume buying agreements that take advantage of economies of scale greatly enhance procurement economics. By consolidating blade requirements across several equipment types, the Dozer Edge-Cutting 107-3746's standardized specifications promote bulk procurement techniques that save prices per unit. Distribution markups, production complexity, and material costs are often reflected in pricing structures. Procurement specialists may negotiate advantageous terms while guaranteeing sufficient supplier margins to maintain quality and service standards by being aware of these aspects.

Quality Assurance and Warranty Considerations

Material certification, dimensional inspection, and performance validation should all be part of quality verification processes prior to acceptance. Reputable vendors provide records attesting to production quality control procedures and material traceability, which guarantee reliable product performance. Although supplier warranties vary, they usually cover premature wear and manufacturing faults under ordinary operating settings. While setting clear performance expectations with suppliers, being aware of warranty coverage and claim processes helps guard against any quality problems.

Practical Installation and Durability Insights for Operational Excellence

For the 107-3746 cutting edge to be implemented successfully, correct installation techniques and continuous monitoring are necessary to guarantee peak performance throughout the course of its service life. High performance criteria are maintained while these procedures are made simpler by the compatible design.

Installation Procedures and Technical Requirements

Verifying the hardware's condition and properly preparing the mounting surfaces are the first steps in installation. The exact specifications of the 107-3746 guarantee simple installation using common equipment and techniques. By adhering to established Caterpillar norms, torque requirements and mounting sequences eliminate uncertainty and shorten installation times. Bolt torque settings, clean mounting surfaces, and correct blade orientation are important installation factors. Adhering to these guidelines guarantees safe and effective cutting geometry and a secure connection.

Performance Monitoring and Maintenance Scheduling

Finding wear patterns and other problems before they affect operation is made easier by setting up routine inspection intervals. Predictable service life predictions are provided by the 107-3746's wear characteristics, which aid in inventory control and scheduled maintenance scheduling. Visual examination of the cutting edge geometry, measurement of the blade's residual material, and assessment of the mounting hardware's condition are all examples of monitoring processes. These evaluations assist maximize blade use and direct replacement timing choices.

Durability Under Varying Operating Conditions

The 107-3746's adaptability to various soil conditions, climatic variables, and operational intensity levels is shown by field testing conducted in a variety of operating scenarios. Regardless of application-specific factors, the blade provides dependable operation by maintaining similar performance characteristics throughout this spectrum of settings. Extremes in temperature, moisture content, and abrasive soil types are examples of environmental elements that affect blade wear rates without compromising the 107-3746's core compatibility and performance attributes, which make it appropriate for Caterpillar 938 Series applications.

SINOBL: Your Trusted Partner for Premium Dozer Edge-Cutting Solutions

SINOBL has established itself as a leading manufacturer and supplier of high-quality ground engaging tools, including the Dozer Edge-Cutting 107-3746 and compatible accessories for Caterpillar equipment. Our extensive experience in heavy machinery components manufacturing ensures reliable supply of precision-engineered parts that meet demanding operational requirements.

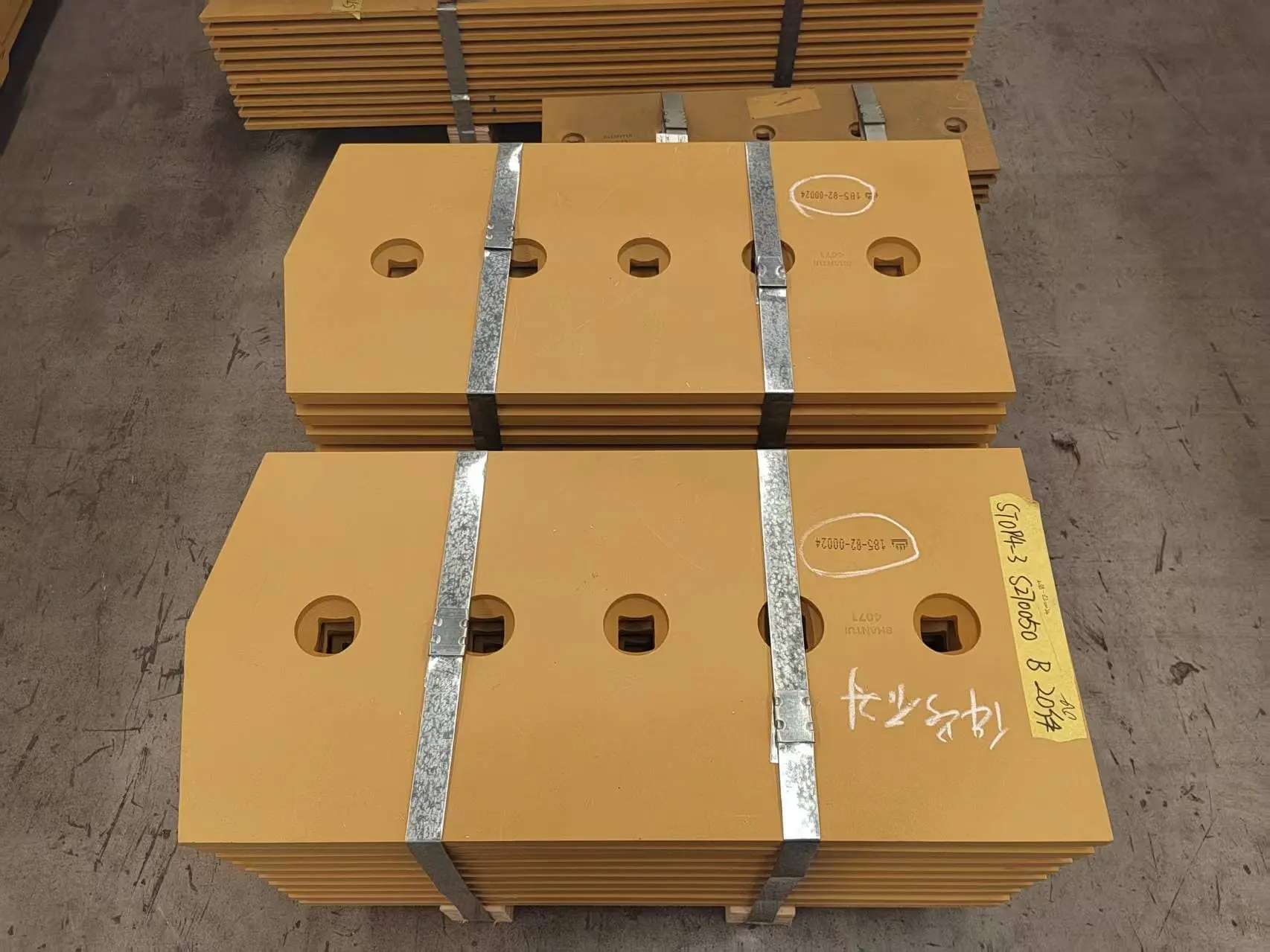

Manufacturing Excellence and Quality Assurance

Modern production methods and strict quality control procedures are integrated into our 55,944 square meter manufacturing plant, which reliably produces parts that satisfy OEM requirements. Cutting edges and end bits may be produced at a rate of 2,500 tons per month, which guarantees consistent supply availability for both individual orders and extensive fleet needs. Material verification, dimensional inspection, and performance testing techniques are all part of quality assurance methods that confirm each component's appropriateness for intended uses. Consistent material qualities that provide predictable service life and performance characteristics are ensured by heat treatment procedures and metallurgical controls.

Comprehensive Product Portfolio and Customization Services

Beyond typical cutting edges, SINOBL offers customizable configurations and unique solutions made to meet certain operating needs. In order to satisfy a wide variety of client preferences and application requirements, OEM and ODM services provide flexibility in terms of dimensions, specifications, color choices, and package solutions. Over 3,000 tons of ready-to-ship components make up the extensive inventory, which satisfies the need for quick delivery while upholding quality standards. With dependable delivery performance, this inventory depth supports scheduled maintenance schedules and allows for quick reaction to urgent replacement demands.

Global Distribution and Technical Support

Through regional alliances and well-established logistical networks, international distribution capabilities guarantee SINOBL goods are available everywhere. In order to assist clients optimize equipment productivity and component service life, technical support services include compatibility verification, application advice, and performance improvement suggestions. Procurement professionals get dependable assistance throughout the supplier relationship according to customer service standards that prioritize timeliness and technical know-how. Because of its dedication to providing exceptional customer service, SINOBL is a top choice for businesses in need of a reliable source for heavy equipment components.

Conclusion

The Dozer Edge-Cutting 107-3746 provides an excellent balance of compatibility, performance, and value for Caterpillar 938 Series applications. Its precision engineering ensures reliable operation while simplified maintenance requirements and proven durability deliver measurable economic benefits. Procurement professionals can confidently specify this cutting edge knowing it will meet operational demands while providing predictable service life and performance characteristics. The widespread availability through qualified suppliers, including SINOBL's comprehensive manufacturing and distribution capabilities, ensures reliable supply support for both immediate needs and long-term fleet maintenance strategies.

Frequently Asked Questions

What specific Caterpillar 938 models are compatible with the 107-3746 cutting edge?

The Dozer Edge-Cutting 107-3746 is engineered for compatibility across the complete Caterpillar 938 Series lineup, including models 938F, 938G, 938H, 938K, and 938M. The standardized mounting configuration and dimensional specifications ensure proper fit and performance across these model variations, eliminating compatibility concerns during procurement and installation.

How does the service life of the 107-3746 compare to OEM cutting edges?

Field testing and user reports indicate that quality aftermarket 107-3746 cutting edges typically match or exceed OEM service life expectations under similar operating conditions. The high-carbon steel construction and specialized heat treatment processes provide wear resistance comparable to original equipment while often offering superior value through competitive pricing and availability.

What warranty coverage is available for bulk purchases of the 107-3746?

Warranty terms for bulk purchases typically include coverage against manufacturing defects and premature wear under normal operating conditions. SINOBL provides comprehensive warranty support with clear claim procedures and rapid response times. Specific terms may vary based on order volume and customer requirements, with extended coverage options available for large fleet applications.

Partner with SINOBL for Your Dozer Edge-Cutting 107-3746 Requirements

SINOBL stands ready to support your ground engaging tool requirements with premium Dozer Edge-Cutting 107-3746 solutions and comprehensive technical expertise. Our proven track record as a reliable supplier ensures consistent quality and delivery performance that meets the demanding schedules of modern construction and mining operations. Contact our team at nancy@sunmach.com.cn for detailed specifications, competitive pricing, and customized procurement solutions tailored to your fleet requirements. Experience the difference that professional manufacturing capabilities and dedicated customer service make in optimizing your equipment performance and operational efficiency.

References

1. Caterpillar Performance Handbook, Edition 52. Caterpillar Inc. Equipment Performance and Operating Cost Guidelines for Heavy Machinery Applications.

2. Smith, Robert J. Ground Engaging Tools: Design and Application in Earthmoving Equipment. Heavy Equipment Publishing, 2023.

3. International Journal of Mining and Construction Equipment. "Wear Analysis of Cutting Edge Components in Abrasive Soil Conditions." Volume 45, Issue 3, 2024.

4. Equipment Management Guidelines for Construction Fleet Operations. Construction Industry Institute, University of Texas, 2023.

5. Anderson, Michael K. Heavy Equipment Maintenance and Component Selection Strategies. Industrial Press, 2024.

6. Global Construction Equipment Market Analysis: Ground Engaging Tools Segment. Equipment Research Institute, 2024.