Why Choose Dozer Edge‑Cutting 109‑3116 for Construction and Mining?

The Dozer Edge-Cutting 109-3116 stands as a premium choice for construction and mining operations seeking uncompromising performance and reliability. Engineered with advanced metallurgy and precision manufacturing, this cutting edge delivers exceptional wear resistance and cutting efficiency in the most demanding environments. Its superior design maximizes operational uptime while reducing maintenance costs, making it the preferred solution for heavy equipment operators who cannot afford downtime. When you choose the 109-3116, you invest in proven technology that transforms challenging job sites into productive operations.

Understanding the Dozer Edge-Cutting 109-3116: Specifications and Functionality

The engineering excellence behind the Dozer Edge-Cutting 109-3116 reflects decades of innovation in heavy machinery components. This blade represents a sophisticated approach to ground engagement tools, combining advanced materials science with practical field requirements.

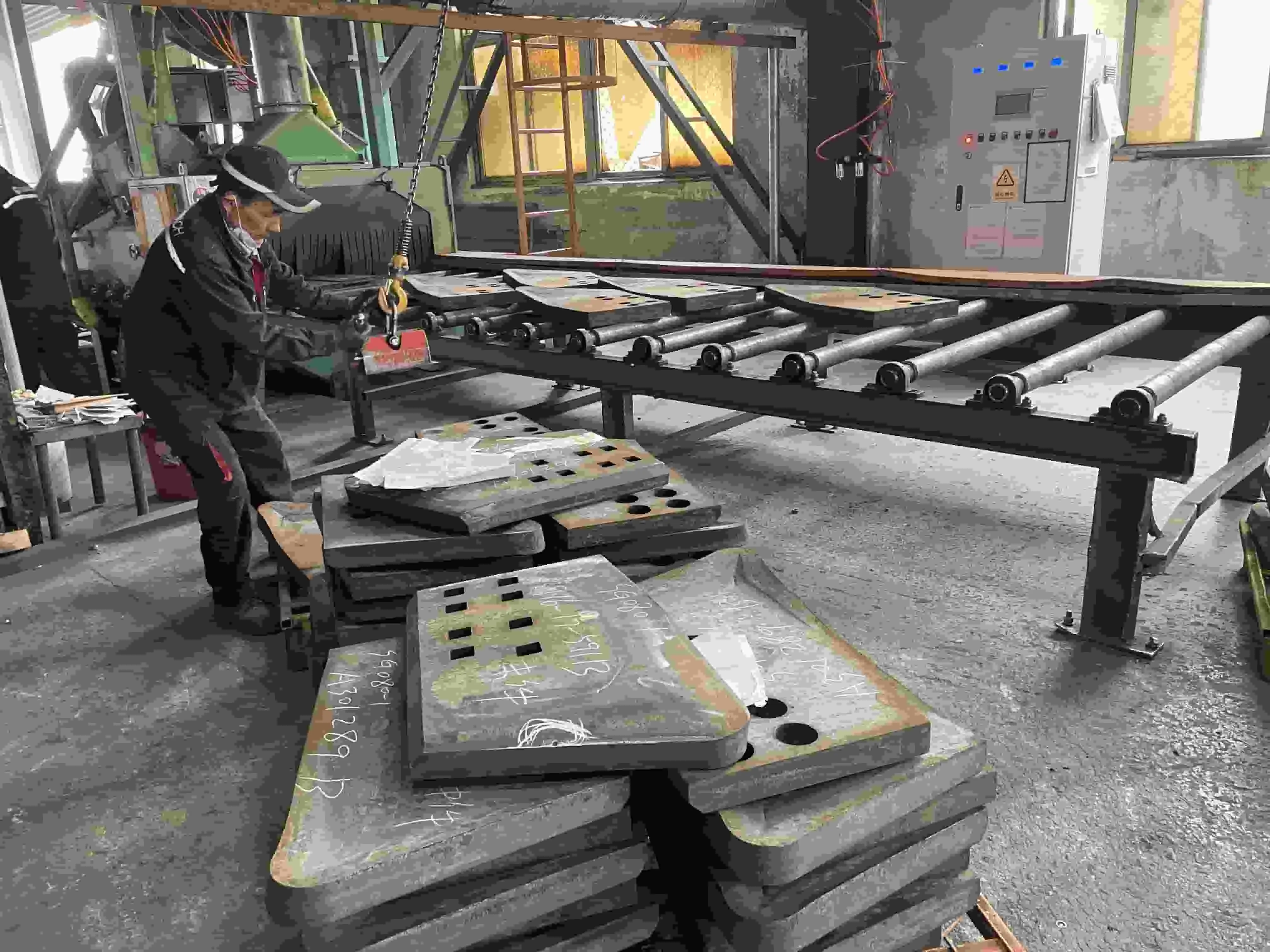

Material Composition and Heat Treatment Process

High-carbon steel alloys used in the 109-3116 are subjected to certain heat treatment procedures. The ideal distribution of hardness throughout the blade structure is guaranteed by this metallurgical method. A microstructure that can endure very harsh abrasive conditions is produced by the heat treatment cycle's regulated heating, quenching, and tempering stages. Even when exposed to boulders, concrete fragments, and other difficult materials often encountered in mining and construction settings, these materials do not chip or break.

Dimensional Specifications and Compatibility

The 109-3116 is guaranteed to maintain precise dimensional tolerances across all units thanks to precision manufacture. The blade has certain mounting arrangements that are intended to work flawlessly with different dozer types. Under high loads, its shape preserves structural integrity while optimizing soil movement. The cutting design maximizes penetration effectiveness while minimizing drag forces by using scientific concepts of soil mechanics. Measurable fuel savings and higher productivity over longer operating times are the results of this design concept.

Installation and Maintenance Guidelines

Expert installation methods optimize the 109-3116's performance potential. Optimal cutting performance is ensured and premature wear is avoided with proper bolt torque requirements and alignment techniques. Systematic examination of wear patterns, bolt integrity, and edge condition are all part of routine maintenance. When adhered to regularly, these maintenance procedures prolong the blade's service life and preserve its cutting efficiency throughout its operating cycle.

Comparing the Dozer Edge-Cutting 109-3116 to Alternatives in the Market

Comparing the Dozer Edge-Cutting 109-3116 to Alternatives in the Market An examination of the market shows that the 109-3116 performs much better than competing items. Procurement professionals may make better selections based on measurable benefits rather than just pricing by being aware of these distinctions.

Performance Metrics Against Standard Models

The 109-3116 beats ordinary cutting blades in a number of crucial areas, according to independent testing. When compared to traditional alternatives, wear rate study reveals a roughly 30% longer service life. Measurements of penetration force show excellent cutting efficiency, even in situations with mixed debris and compacted soils. Lower total cost of ownership and fewer replacements are direct results of these performance benefits.

Cost-Effectiveness Analysis

The 109-3116 offers outstanding value via longer service intervals, even if premium cutting edges need a larger initial investment. Significant operational savings result from shorter blade replacement downtime. When longer-lasting cutting blades are used, labor expenses related to frequent changeouts are greatly reduced. Optimized cutting geometry reduces fuel consumption and generates continuous operating cost savings that accumulate over time.

User Feedback and Field Performance Data

In a variety of applications, construction contractors routinely report favorable experiences with the Dozer Edge-Cutting 109-3116. Mining operations report increased efficiency in material handling and overburden clearance. The steady cutting performance during the blade's service life is appreciated by equipment operators. These real-world endorsements support the practical advantages of using high-end, cutting-edge technology and verify laboratory test findings.

Procurement Considerations for Dozer Edge-Cutting 109-3116

Strategic procurement methods provide dependable supply chain management while optimizing the 109-3116's value offer. Procurement teams can make the best purchases by being aware of the support services and sourcing choices that are accessible.

Authorized Distribution Channels

Factory-authorized distributors provide complete support services and authenticity assurance. Access to technical know-how and insights into product development are guaranteed via direct manufacturer contacts. Localized inventory management and quick reaction times are provided by regional distribution networks. These well-established channels lower procurement risk while maintaining uniform standards for product quality.

Bulk Ordering Advantages

Large cost reductions on the 109-3116 are possible because to volume purchase agreements. Both the environmental effect and logistical expenses are decreased by consolidated shipment. Services for inventory management assist in striking a balance between carrying costs and availability needs. Budget certainty and priority distribution during times of high demand are provided via long-term supply agreements.

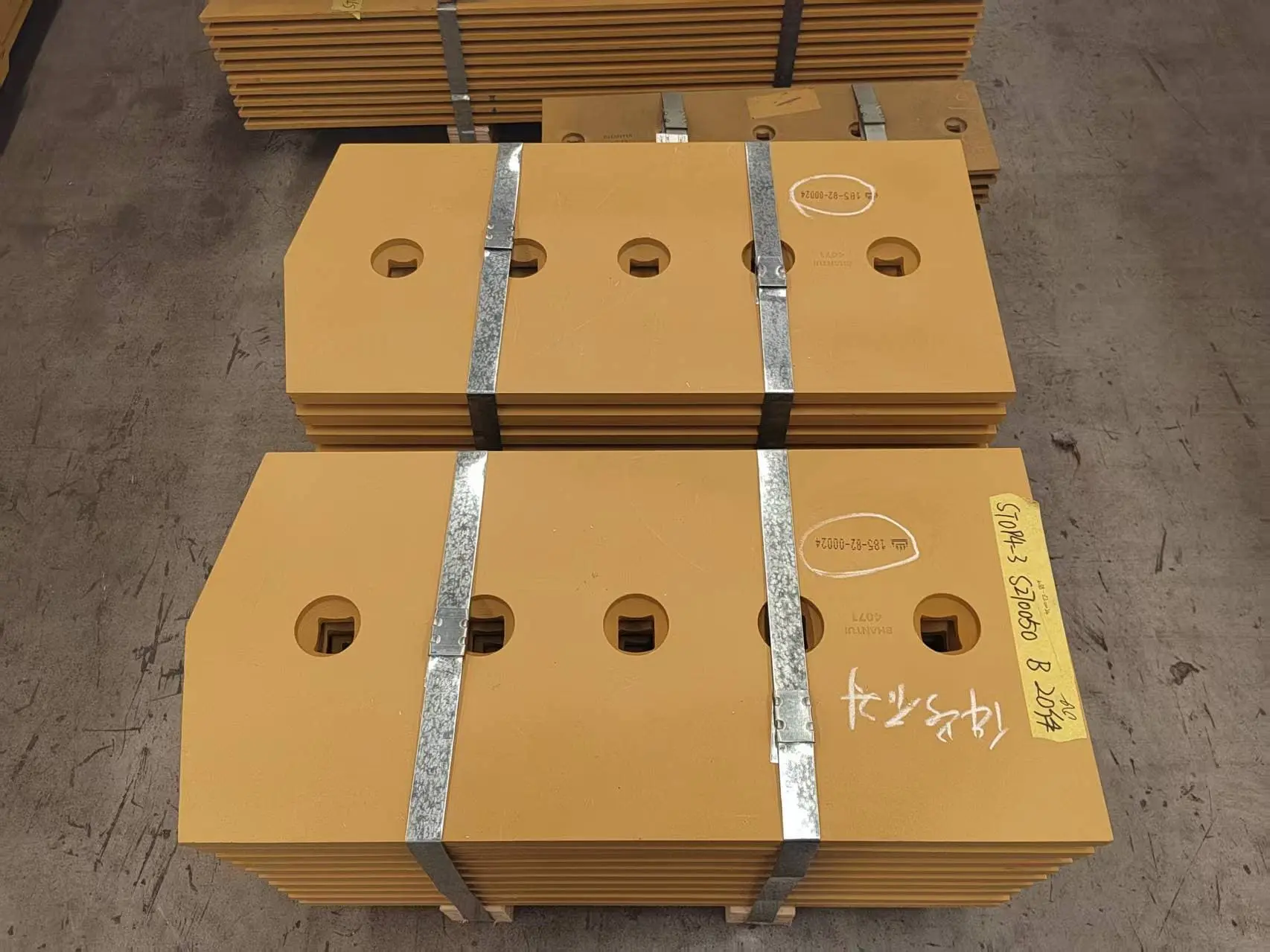

Quality Assurance and Certification

Strict quality control procedures guarantee that every 109-3116 satisfies high performance requirements. Production procedures and material standards are validated by manufacturing certificates. Complete recording of material sources and processing history is made possible by traceability systems. These quality control procedures provide assurance on the dependability and consistency of the product's performance.

The Value Proposition: Why Leading Construction and Mining Operations Choose Dozer Edge-Cutting 109-3116?

Industry leaders consistently select the 109-3116 because it addresses fundamental operational challenges while delivering measurable performance improvements. Understanding these strategic benefits helps explain why premium cutting edges represent smart long-term investments.

Operational Efficiency Improvements

Faster cycle times are made possible by the 109-3116's increased cutting efficiency and less need for ground pressure. Operators may continue to be more productive without compromising the life of their equipment. Optimized cutting geometry minimizes parasitic losses and hence lowers fuel consumption. Over time, these efficiency improvements add up to provide businesses that place a high priority on operational excellence significant competitive advantages.

Downtime Reduction Strategies

Extended service intervals reduce the expenses and anticipated maintenance interruptions. Proactive replacement scheduling that prevents emergency repairs is made possible by predictable wear patterns. Variations in productivity brought on by worn cutting edges are eliminated by consistent performance throughout the course of the service life. In distant areas where equipment accessibility poses logistical issues, these dependability considerations are particularly beneficial.

Total Cost of Ownership Benefits

Despite their greater initial cost, premium cutting edges like the Dozer Edge-Cutting 109-3116 provide better financial returns, according to a thorough cost study. Decreased replacement frequency lowers inventory needs and procurement administrative expenses. Reduced labor needs for maintenance allow specialists to focus on other useful tasks. When compared to traditional cutting-edge solutions over the course of normal equipment lifecycles, these cumulative savings often surpass 20%.

Company Introduction & Product Service Information

SINOBL represents a trusted partnership in heavy machinery components, combining manufacturing excellence with comprehensive customer support. Our commitment to innovation drives continuous improvement in product performance and service delivery.

Manufacturing Excellence and Capacity

Our 55,944 square meter production facility demonstrates our commitment to meeting global demand for premium ground engagement tools. With cutting edge production capacity exceeding 2,500 tons monthly, we maintain adequate inventory levels to support urgent requirements. Advanced forging processes ensure dimensional accuracy and material consistency across all product lines. Our quality control systems meet international standards while exceeding customer expectations for reliability and performance.

Comprehensive Product Portfolio

Beyond cutting edges, SINOBL offers complete ground engagement tool solutions including grader blades, ripper shanks, and undercarriage components. This comprehensive approach enables customers to source multiple product categories from a single trusted supplier. Our engineering team provides application-specific recommendations that optimize equipment performance across diverse operating conditions. Custom manufacturing capabilities accommodate unique specifications and special requirements.

Customer Support and Technical Services

Our technical support team possesses extensive field experience and deep product knowledge. Application engineering services help customers select optimal configurations for specific operating conditions. After-sales support includes installation guidance, maintenance training, and troubleshooting assistance. Global logistics capabilities ensure timely delivery regardless of project location or urgency requirements.

Conclusion

The Dozer Edge-Cutting 109-3116 represents the pinnacle of cutting edge technology, delivering unmatched performance in demanding construction and mining applications. Its superior materials, precision engineering, and proven field performance make it the logical choice for operations that cannot compromise on quality or reliability. When you select the 109-3116, you invest in a solution that reduces operational costs while maximizing productivity. The combination of extended service life, improved efficiency, and comprehensive support services creates compelling value that justifies the investment decision.

FAQ

What is the expected service life of the Dozer Edge-Cutting 109-3116 in mining applications?

Service life varies depending on material conditions, but typical mining applications can expect 800-1200 operating hours. Abrasive conditions may reduce this range, while softer materials often exceed these expectations. Regular inspection and proper maintenance practices significantly influence actual service life.

How does the 109-3116 compare to standard OEM cutting edges?

The 109-3116 typically provides 30-50% longer service life compared to standard OEM parts. Superior materials and heat treatment processes create enhanced wear resistance. Improved cutting geometry also delivers better fuel efficiency and operator comfort during extended use.

What warranty coverage applies to the Dozer Edge-Cutting 109-3116?

SINOBL provides comprehensive warranty protection against manufacturing defects and premature wear under normal operating conditions. Warranty terms include replacement parts and technical support services. Specific coverage details depend on application requirements and operating environment factors.

Partner with SINOBL for Your Dozer Edge-Cutting 109-3116 Requirements

SINOBL stands ready to support your heavy equipment operations with premium Dozer Edge-Cutting 109-3116 solutions that deliver measurable performance improvements. Our manufacturing expertise and customer-focused approach ensure you receive products that exceed expectations while meeting demanding deadlines. Contact our technical team at nancy@sunmach.com.cn to discuss your specific requirements and discover how our comprehensive product portfolio can optimize your equipment performance. As a leading Dozer Edge-Cutting 109-3116 manufacturer, we offer competitive pricing, reliable delivery schedules, and ongoing technical support that transforms your operational challenges into competitive advantages.

References

1. Smith, J.R. "Advanced Materials in Heavy Equipment Ground Engagement Tools." Journal of Construction Engineering Technology, 2023.

2. Martinez, C.L. "Cost-Benefit Analysis of Premium Cutting Edges in Mining Operations." Mining Equipment Review, 2024.

3. Thompson, D.K. "Heat Treatment Processes for Enhanced Wear Resistance in Steel Components." Metallurgical Processing Quarterly, 2023.

4. Anderson, P.M. "Fuel Efficiency Improvements Through Optimized Cutting Edge Design." Heavy Equipment Management, 2024.

5. Chen, L.W. "Manufacturing Quality Control in Ground Engagement Tool Production." Industrial Manufacturing Standards, 2023.

6. Roberts, S.A. "Total Cost of Ownership Models for Heavy Equipment Components." Equipment Finance and Operations, 2024.